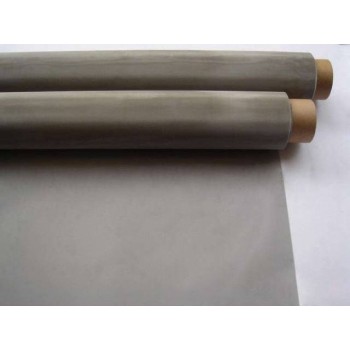

Titanium Screen

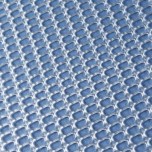

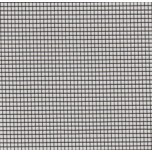

Grade 1 Titanium Screens are primarily used in electrolyzer stacks as part of the flow field or diffuser material, particularly on the Oxygen (anode) side, in place of the carbon-based Gas Diffusion Layers (GDL) used in fuel cells. Our titanium screens are produced from expanded titanium that has been flattened and annealed, ensuring a smooth, flat surface suitable for use in electrolyzer or fuel cell stacks. Although most commonly used on the Anode side of an electrolyzer, titanium screens are often used on the Cathode side of the electrolyzer as well. Occasionally they can be found in fuel cells as well.

Why not use a Carbon based Gas Diffusion Layer in an Electrolyzer?

Carbon based GDL materials will be consumed and converted into CO2 gas in the presence of the Oxygen ions and Voltage found on the Anode (Oxygen) side of the electrolyzer. This secondary reaction of oxidizing the Carbon in the GDL will give temporarily lower electrolysis voltage, but this is a short lived phenomenon. The carbon GDL is quickly consumed, resulting in poor compression in the stack, and thus high resistance and lower performance.

You can still used carbon cloth or carbon paper material on the Hydrogen side (cathode) since there is oxygen on that side that will oxidize the GDL material.

Should I use a Platinized Titanium Screen?

Untreated Titanium will not be consumed as a carbon Gas Diffusion Layer (GDL) will, however, the presence of the Oxygen does have an impact. Untreated Titanium quickly forms an Oxide coating (TiO2) in the presence of oxygen. This coating is an excellent insulator and will therefore increase the resistance in the cell, thereby lowering performance. This takes longer to be evident as a problem than the oxidation of the carbon GDL, but is still a factor.

The oxidation of Titanium can be prevented by Gold coating or Platinum coating the Titanium. The platinization is a very stable coating and also helps to promote the electrolysis process, increasing efficiency slightly and stabilizing performance dramatically.

| Thickness | Strand Width | Long Way of Diamond | Percent Open Area | Aerial Weight |

| 0.002 | 0.004 | 0.031 | 62% | 0.008 g/cm2 |

| 0.004 | 0.006 | 0.031 | Undisclosed | 0.024 g/cm2 |

| 0.005 | 0.010 | 0.125 | 64% | 0.019 g/cm2 |

| 0.007 | 0.007 | 0.125 | 75% | 0.019 g/cm2 |

| 0.010 | 0.012 | 0.125 | 57% | 0.049 g/cm2 |

Write a review

Your Name:

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: